Analysis

“During my 17 years experience as NOVEXA’s CEO, I have witnessed from factories of the different industrial groups that they do not have the time or the necessary ressources to perform objective monitorings of open gears.”

Fabrice ZIEGLER - CEO

The different monitoring tools currently used in the industry are:

- Manufacturer audits – most of the time not objective, they often conclude with the necessity of supply of new equipment

- Lubricant suppliers audits – lack of technical information and do not take into account the potential issues linked to gears geometrical characteristics.

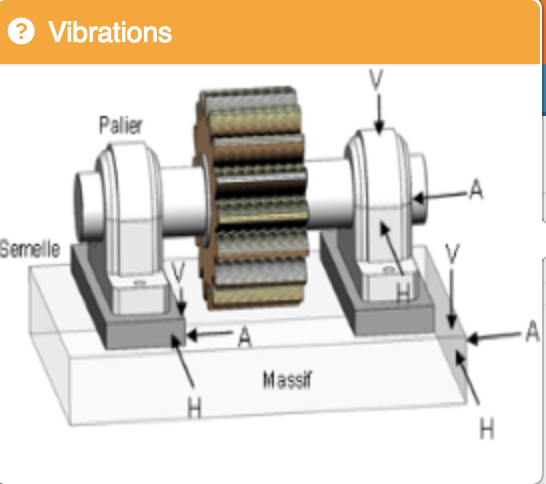

- Vibrations analysis – only highlight the consequences of damages (foundation cracks, excessive bearing clearance, damaged anchor, root step clearance problem…)

This is why, my teams and I, we have developped the Xcase, the first and unique tools allowing you to carry out a preventive maintenance plan.

Thanks to this tool, your teams will stay autonomous and will gain technical knowledge.

The XCase target

Monitoring of vibrations or temperatures only allows highlighting damages

Gears profiles monitoring allows anticipating damages

More than a simple tools, the XCase is a complete decision making solution

The XCase, the first tools gathering in 1 application the monitoring of:

- Gears

- Vibrations

- Temperatures

- Technical characteristics

- History

Required data

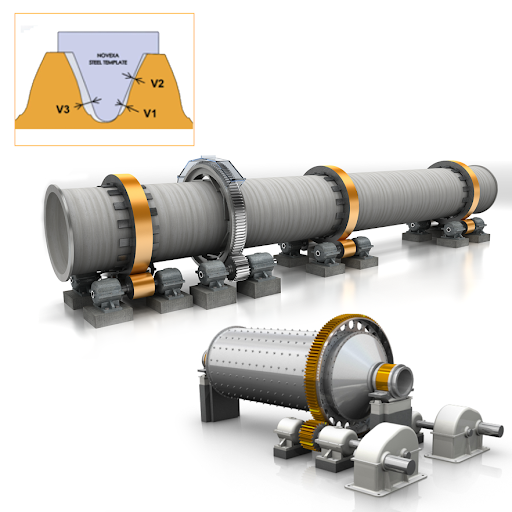

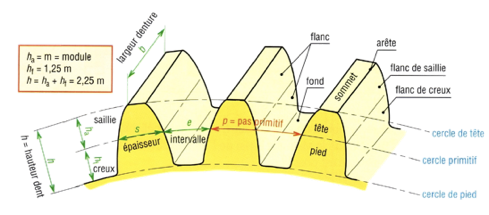

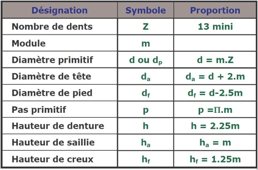

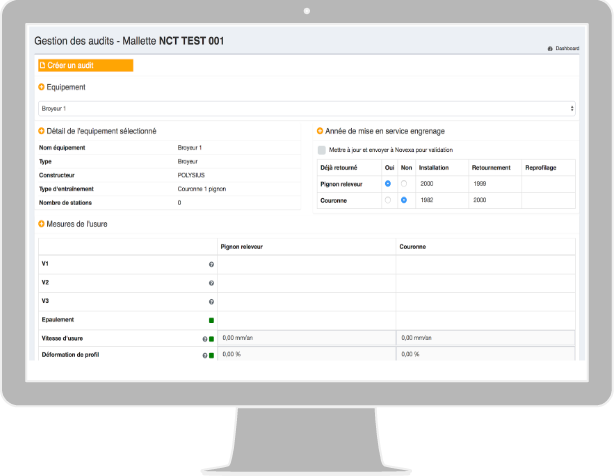

The following characteristics will have to be gathered for each equipment in order to manufacture the associated steel templates:

- Module (m)

- Pressure angle (α)

- External diameter (da)

- Number of teeth (z)

- Helix angle (β)

Gear history is also required:

- Date of installation

- Date of gear reversing

- Date of pinion replacement

Parameters to measure during audit

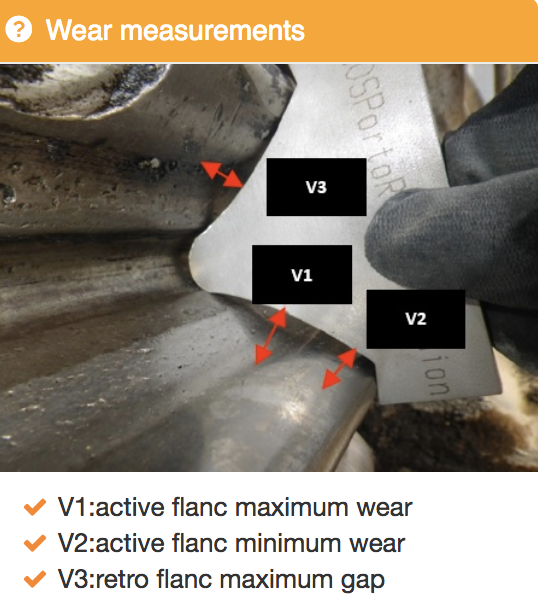

XCase is based on the use of control templates. They allow to accurately measure the profile deformation through 3 simple measurements:

- V1 = maximum wear

- V2 = minimum wear

- V3 = non working side maximum gap

To complete the analysis :

- Vibrations readings on bearings, bedplates and foundations

- Pinion / gear temperature readings

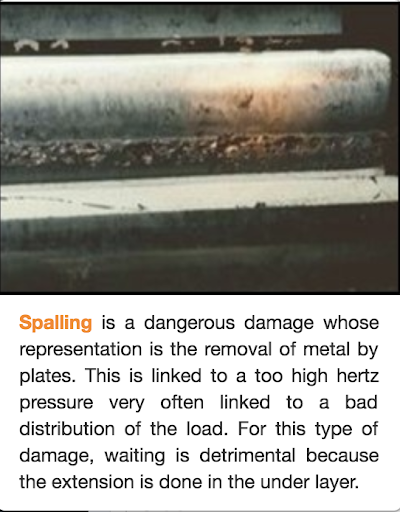

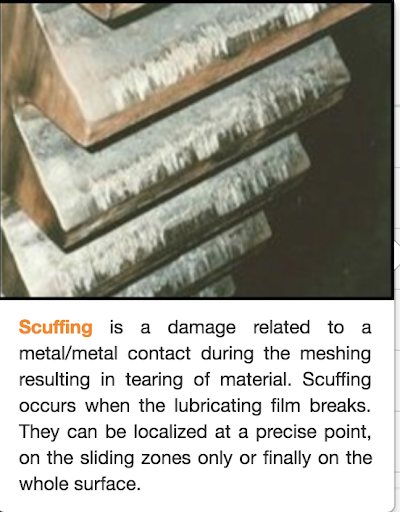

- Surface damages pictures

With this simplified control, all color codes are automatically calculated and appear instantly on the application.

What you will find in the XCase

All in One :

The XCase includes :

- Transportable briefcase

- User manual

- Access code

- Fealure gauge

- Gear and pinion steel templates (V1, V2 ,V3)

- Vibration pen (mm/s - RMS)

Create an audit

Creating a new audit with the "Audit Management" menu

Audits reports are generated when you decide it (Remote access 24h a day, 7 days a week )

Your teams maintain control on audits and their maintenance schedule.Experts on site stay autonomous

Average time for measurements on site :- 45 min with equipment stopped

- 25 min in production

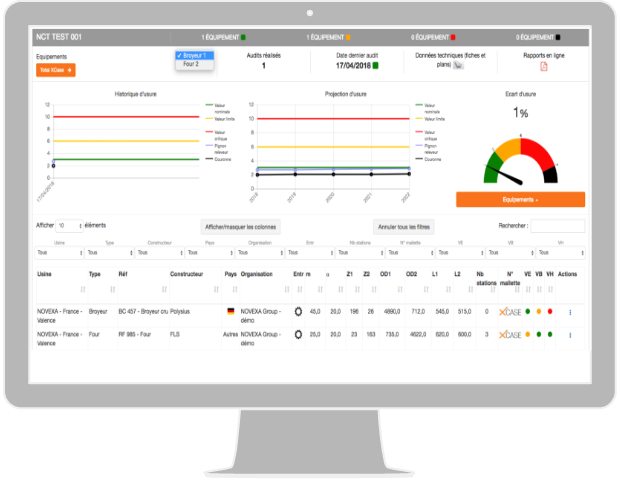

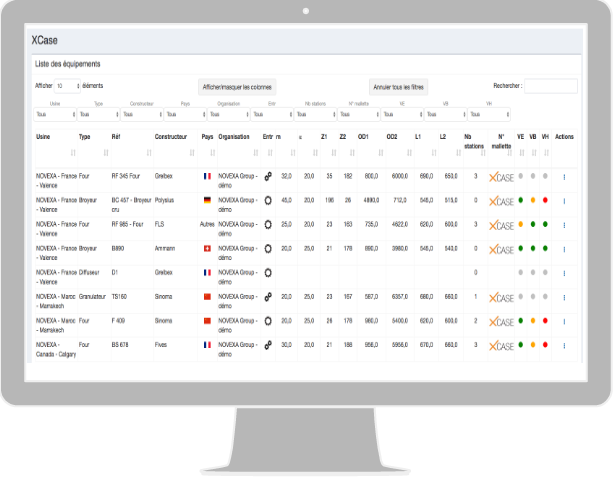

XCase application

- -Simplified reading thanks to NOVEXA color codes

- -History + wear projection through 2 separated graphs

- -Cursor on the right helps you reading risks linked to equipment wear

- -Date of last audit

- -Access to technical data

- - Switch to another equipment in one click through the drop-down menu

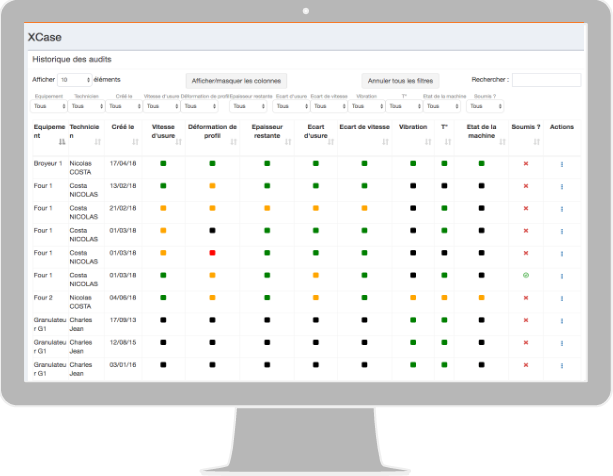

Audit records access

Accurate

Sorting is possible via 11 criteria available. This allows accurate and quick equipment monitoring, especially with:

- Remaining thickness → helps deciding between replacement and reprofiling

- Wear speed → allows forecasting maintenance actions and budget

- Wear distortion → gives information on risk of vibration increase

Sharing and security

Exportable

Novexa make it easy to share information with a reports structure sorted by files, and which can be downloaded in PDF format.

Communication

The API developed by Novexa offers the possibility of interfacing with your existing IT tools.

Data safety

Data are encrypted and stored according to HTTPS protocol, making them completely secured.

NOVEXA

In the world